Mikkeli Waterworks’ new Metsä-Sairila wastewater treatment plant is one of the most modern in the world. A treatment plant based on MBR, membrane bioreactor technology, was built inside the bedrock. This minimised potential harm to the environment and at the same time provided good conditions for the process and maintenance. The treatment plant’s process automation and instrumentation project was started in the summer of 2019 and the plant was commissioned in May 2021. In addition to the wastewater treatment plant, Mipro’s MISONET automation system also included the Kenkäveronniemi inlet pumping station and the Salosaari measuring station.

The treatment plant is based on the MBR process which is the most modern technology in the world. The project is one of the most significant in the water supply sector in Mipro’s history and unique in Finland; never before has this technology been utilised on this scale in a Finnish wastewater treatment plant. However, there are already many wastewater treatment plants in the world based on the MBR process; excellent results can be expected in terms of cleaning.

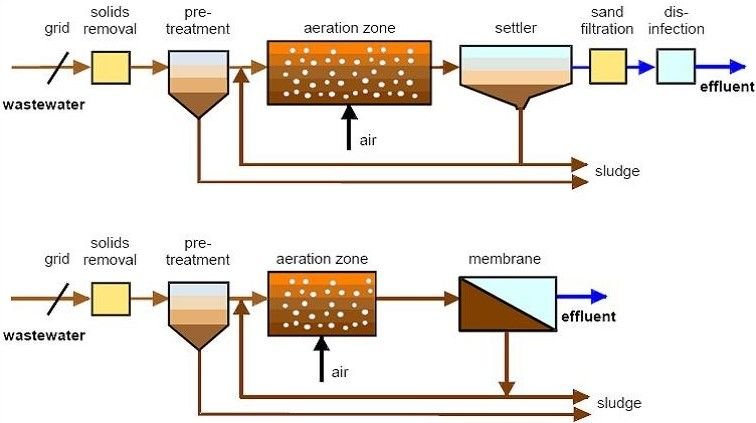

With MBR technology, clean water is separated through an extremely small-pore membrane after efficient biochemical treatment. This technique achieves a better cleaning result than traditional methods; based on the operating results of the first year, Metsä-Sairila treatment plant has already reached far better results than the reference values require. The phosphorus content in the leaving water is 0.05 mg / l, while the reference value allowed in the permit conditions is 0.30 mg / l. These cleaning results are achieved by combining the benefits of the process-based MBR technology and intelligent automation.

Image: Differences in wastewater treatment plant processes based on traditional technology and MBR technology.

What does the process automation provided by Mipro at the new treatment plant do and what does it enable?

The need to build new treatment plants arises when the cleaning results in the old ones decline for one reason or another. One of the most common reasons for the decline of the cleaning results is the aging of the plant and technology at the same time as the requirements for cleaning results are tightening. The modernisation of plant infrastructure and automation will result in better cleaning results than required, as well as solutions that will last for decades. The intelligent, comprehensive and reliable automation that controls the operation is able to guarantee a good cleaning result and usability.

Mipro’s MISONET automation system monitors, controls and regulates the entire treatment plant’s water processes. The automation system guarantees precise adjustability, which is reflected in excellent cleaning results. High availability and system security, even in more challenging conditions, are guaranteed by duplicated technology. This, combined with modern cleaning technologies, allows for results that fall below the limit values specified in the permit conditions. Comprehensive instrumentation provides a wealth of real-time data from the facility, making process optimisation even easier and more efficient; hundreds of measurements and indicators can be used for energy saving activities and the optimisation of chemical consumption with the help of various KPIs. The control room system (HMI – Human-Machine Interface) included in Mipro’s MISONET automation system provides operators with a real-time picture of the plant operation and automation, as well as visual and graphical figures. The control room system also works in a mobile interface that can easily move anywhere with the operator.

The cleaning results achieved by combining automation and MBR technology provided by Mipro are therefore truly impressive; even so impressive that other end users in the area can use the purified water in their own operations. The Eco-Sairila project, which is developing in the Metsä-Sairila area, operates on the principle of a circular economy, uniting a wide range of companies and public sector, forming a unique innovation ecosystem. Recycled water supplied by Metsä-Sairila is one of the most important elements that enable many companies to operate in the area. (ecosairila.fi)

Water that does not go to reuse is discharged into the lake Saimaa. This purified Metsä-Sairila discharge water is so clean that it even cleans Saimaa. Clean discharge water reduces, among other things, the eutrophication of water bodies and thus, in the long run, leads to even better water quality in the area’s water system. We are proud to be able to share our expertise in projects where new cleaning technology, combined with modern automation, creates excellent results: both for the treatment plants being built and the environment in the area.

Video: Metsä-Sairila’s new wastewater treatment plant process automation and instrumentation

Read more:

Author

Aki Muinonen

Senior Sales Manager

Aki, who started his career at Mipro in 1994, has been working on projects in the water and energy business for 27 years. Having started his career as a project engineer, Aki has extensive experience in the technical and project implementations of Mipro’s solutions. As a Senior Sales Manager, Aki leads the sales of water and energy operations and actively participates in the delivery of systems in several important projects.